Cargo Integrity Group publishes list of cargoes of concern that can compromise supply chain safety

A few days ago, the Cargo Integrity Group, an initiative of the International Cargo Handling Coordination Association – ICHCA, published a list of 15 “cargoes of concern” that are normally transported in containers and whose hazardous nature is not always so obvious, such as the potential danger of lithium-ion batteries. For example, the list contains important information on the flammable properties of seed cakes or the dangers associated with cocoa butter or vegetable oils.

One Response

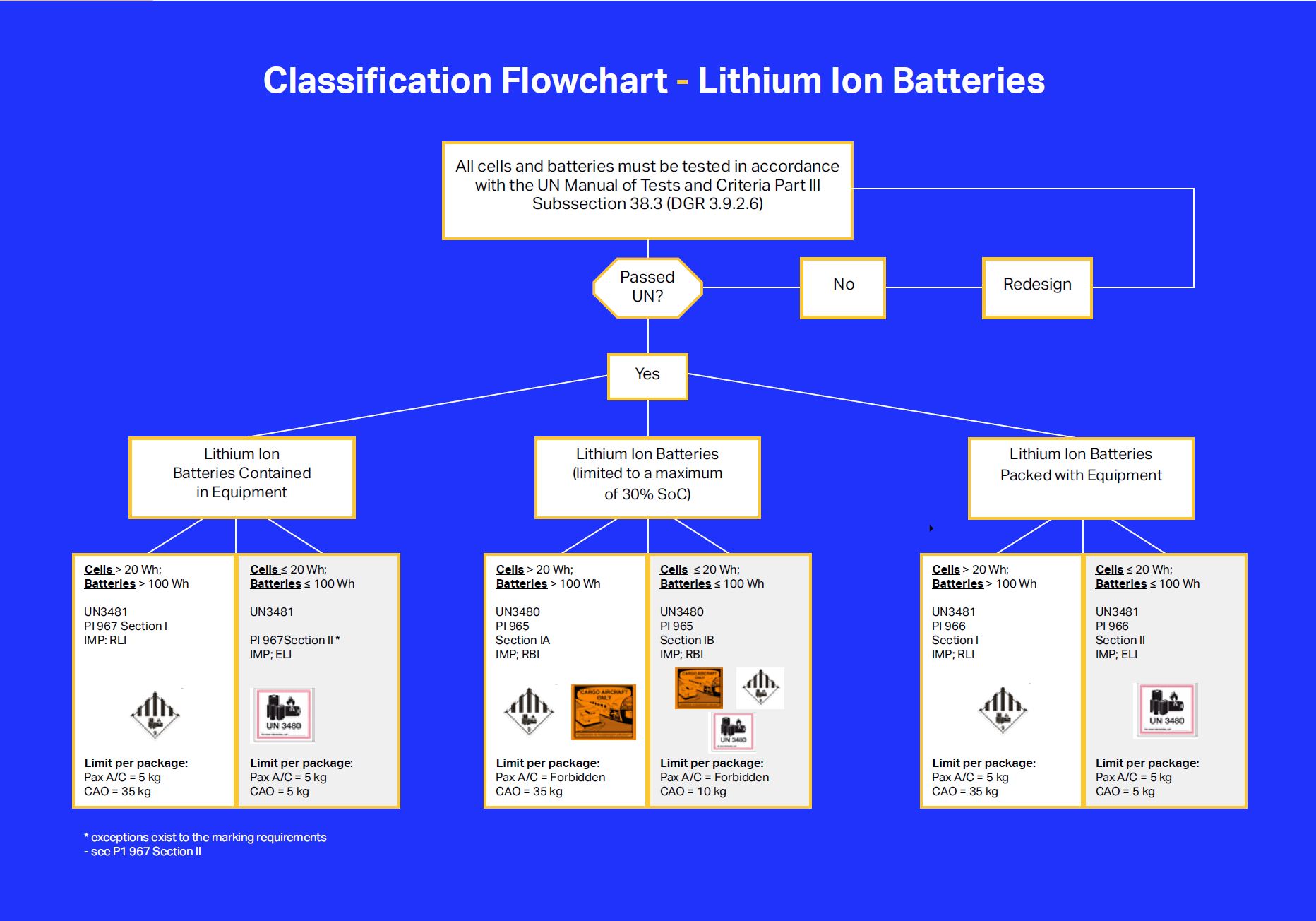

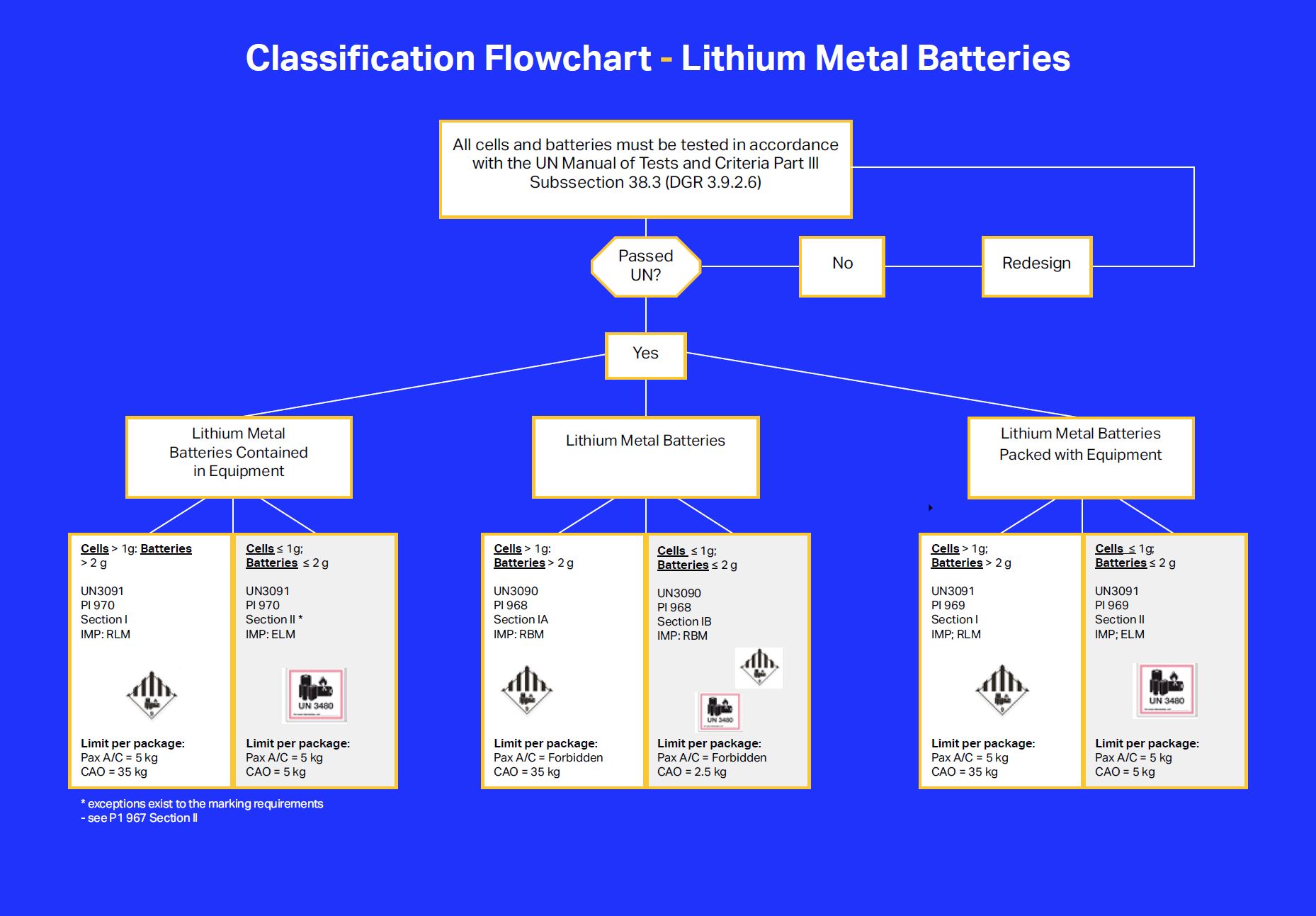

At the most recent meeting of the International Civil Aviation Organisation’s (ICAO) Dangerous Goods Committee, it was decided that in future, lithium-ion batteries packed together with devices must not exceed a state of charge of 30 percent. Previously, this maximum charge level limit only applied to batteries that were transported by air alone. For batteries that are not packed “with” but “in” devices, e.g. in laptop computers, in toys or in medical devices, the 30 per cent upper limit only applies as a recommendation, not as a mandatory requirement. A recommendation is also only made for battery-powered vehicles.

A transitional period of one year and a de minimis limit of 2.7 Wh apply to the new regulation. The new regulation therefore does not apply to weaker batteries. There are also exemptions, but these must be applied for. In principle, the ICAO’s decision must still be confirmed at a further meeting before it is officially published in 2025/26 and subsequently declared binding by the IATA as a legal publication. There are also currently no plans to apply these regulations to road transport or shipping logistics.

It is therefore very important for anyone involved in the shipping of batteries to keep up to date with all announcements over the coming months.